Construction materials

Construction materials represent a broad product category that requires multiple approval types to be successfully imported into Customs Union countries such as Russia, Belarus, Kazakhstan, Armenia, and Kyrgyzstan, as well as other CIS countries including Ukraine, Uzbekistan, and Tajikistan. Since existing standards are not harmonized across the CIS region, each country requires its own certificate, declaration, or other approval document in accordance with national legal requirements.

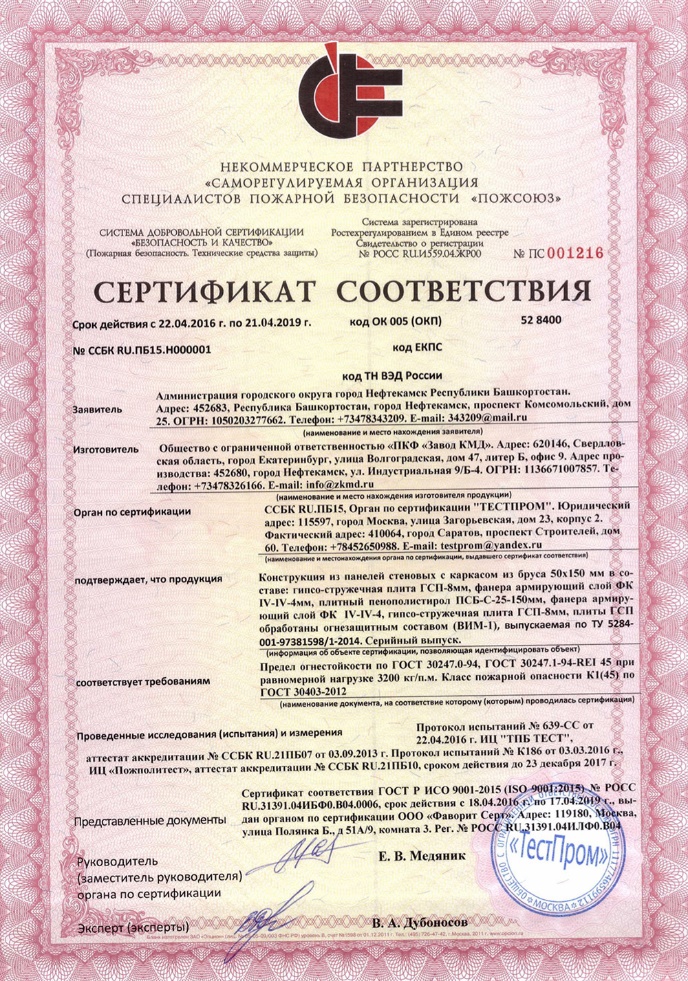

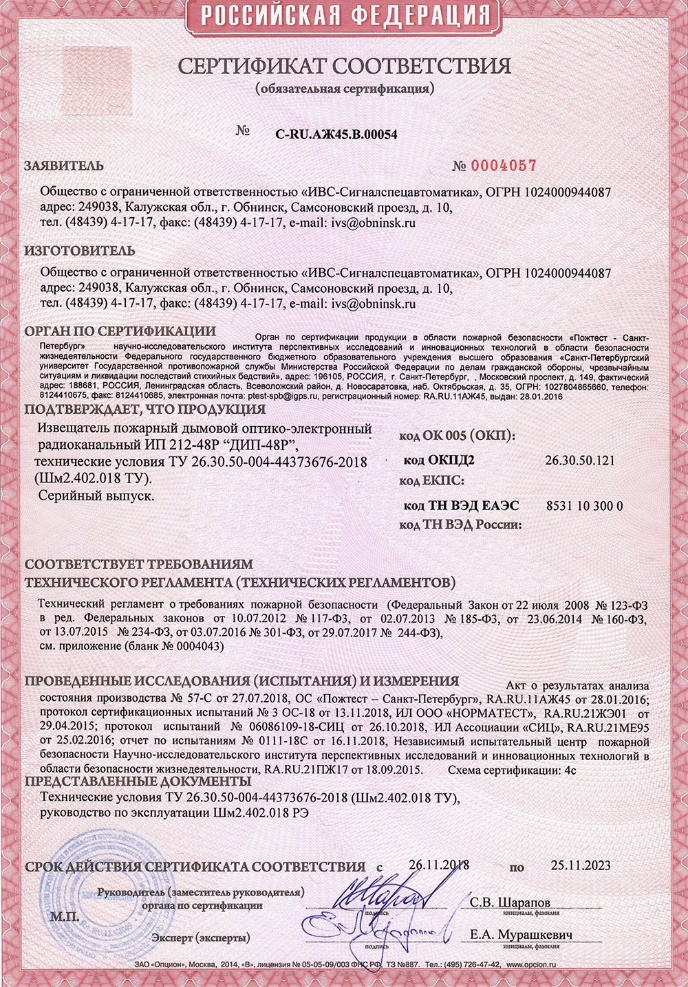

Fire Safety Certificate

A fire safety certificate confirms the safety of a product that has passed fire safety tests and complies with the technical regulations governing fire safety in Russia. This document is currently the most important, as without it, you will not be able to sell products subject to fire safety requirements, nor will you be able to begin construction, as virtually any construction project uses materials that require this permit.

Registration of a fire certificate.

A fire certificate is usually issued for the following materials:

- building materials;

- heat and sound insulating materials;

- floor covering;

- roofing and waterproofing materials;

- metal building structures;

- electrical equipment;

- cable products;

- heat generating devices;

- fire safety equipment.

Technical Regulation No. 123 establishes a list of products subject to fire safety requirements. Products not included in this list can be voluntarily issued a fire safety certificate , and the procedure is the same. The document is issued based on successful testing, after which a test report is prepared, which reflects the product's performance and characteristics.

Fire certification of building materials

In fire certification, the performance indicators of building materials are based on their properties and ability to form fire hazards.

They are characterized by the following properties:

- Flammability

- Flammability

- Ability to spread flame over a surface

- Smoke-forming capacity

- Toxicity of combustion products

|

Properties |

Fire hazard class of building materials depending on groups |

|||||

|

KM0 |

KM1 |

KM2 |

KM3 |

KM4 |

KM5 |

|

|

Flammability |

NG |

G1 |

G1 |

G2 |

G3 |

G4 |

|

Flammability |

- |

B1 |

B2 |

B2 |

B2 |

B3 |

|

Smoke-forming capacity |

- |

D2 |

D2 |

D3 |

D3 |

D3 |

|

Toxicity of combustion products |

- |

T2 |

T2 |

T2 |

T3 |

T4 |

|

Ability to spread flame over a surface |

- |

RP1 |

RP1 |

RP2 |

RP2 |

RP4 |

According to flammability, building materials are divided into combustible ( C ) and non-combustible ( NC ).

During the fire certification process of building materials, their fire hazard class is determined:

Values of building materials at which they are considered non-combustible :

- Temperature increase no more than 50 C

- Sample mass loss is no more than 50%

- The duration of stable flame combustion is no more than 10 seconds

The importance of building materials when they are classified as flammable :

1) G1 – low-flammability:

- Flue gas temperature no more than 135 C

- The degree of damage along the length of the sample is no more than 65%

- The degree of damage by sample weight is no more than 20%

- Self-combustion duration 0 seconds

2) G2 – moderately flammable:

- Flue gas temperature no more than 235 C

- The degree of damage along the length of the sample is no more than 85%

- The degree of damage by sample weight is no more than 50%

- The duration of independent combustion is no more than 30 seconds

3) G3 – normally flammable:

- Flue gas temperature no more than 450 C

- The degree of damage along the length of the sample is no more than 85%

- The degree of damage by sample weight is no more than 50%

- The duration of independent combustion is no more than 300 seconds

4) G4 – highly flammable:

- Flue gas temperature over 450 C

- The degree of damage along the length of the sample is more than 85%

- The degree of damage by sample mass is more than 50%

- Duration of independent combustion is more than 300 seconds

According to flammability, combustible building materials are divided into the following groups:

- B1 – flame-retardant (heat flux density over 35 kW/m2)

- B2 – moderately flammable (heat flux density of at least 20, but not more than 35 kW/m2)

- B3 – flammable (heat flux density less than 20 kW/m2)

According to the rate of flame spread, building materials are divided into the following groups:

- RP1 – non-propagating (heat flux density over 11 kW/m2)

- RP2 – low-spreading (heat flux density of not less than 8, but not more than 11 kW/m2)

- RP3 – moderately spreading (heat flow density of not less than 5, but not more than 8 kW/m2)

- RP4 – highly radiating (heat flux density less than 5 kW/m2)

According to their smoke-forming ability, building materials are divided into the following groups:

- D1 – low smoke-forming capacity (smoke formation value less than 50 m2/kg)

- D2 – moderate smoke-forming capacity (smoke formation rate not less than 50 m2/kg, but not more than 500 m2/kg)

- D3 – high smoke-forming capacity (smoke formation k more than 500 m2/kg)

According to toxicity, building materials are divided into the following groups:

- T1 – low hazard

- T2 – moderately hazardous

- T3 – highly hazardous

- T4 - extremely dangerous

|

Hazard class |

Toxicity index of combustion products depending on exposure time |

|||

|

5 minutes |

15 minutes |

30 minutes |

60 minutes |

|

|

low-hazard |

more than 210 |

more than 150 |

more than 120 |

more than 90 |

|

moderately hazardous |

more than 70, but not more than 210 |

more than 50, but not more than 150 |

more than 40, but not more than 120 |

more than 30, but not more than 90 |

|

highly hazardous |

more than 25, but not more than 70 |

more than 17, but not more than 50 |

more than 13, but not more than 40 |

more than 10, but not more than 30 |

|

extremely dangerous |

no more than 25 |

no more than 17 |

no more than 13 |

no more than 10 |

Fire certification of building materials confirms their suitability for use in specific conditions. Samples are selected for testing. The list of required parameters to be confirmed during fire certification depends on the intended use of the building materials:

- Materials for finishing walls and ceilings, including coatings of paints, enamels, and varnishes:

- Flammability group

- Flammability group

- Smoke-forming ability group

- Combustion product toxicity group

- Floor covering materials, including roofing:

- Flame Spread Group

- Flammability group

- Smoke-forming ability group

- Combustion product toxicity group

- Roofing materials:

- Flammability group

- Flame Spread Group

- Flammability group

- Waterproofing and vapor barrier materials with a thickness of more than 0.2 mm

- Flammability group

- Flammability group

- Thermal insulation materials

- Flammability group

- Flammability group

- Smoke-forming ability group

- Combustion product toxicity group

Fire certification of substances and materials

- Non-flammable – substances and materials that are not capable of burning in air

- Slowly combustible – substances and materials that can burn in air when exposed to an ignition source, but are not capable of burning on their own after its removal

- Combustibles are substances and materials that can spontaneously ignite.

In the process of fire certification of substances and materials, flammability test methods are established by regulatory documents on fire safety.

Fire certification of buildings and structures

Fire certification of buildings and structures is necessary to determine the degree of participation of building structures in the development of a fire (the formation of dangerous fire factors), to determine the purpose and operating characteristics of buildings and structures, and to determine the fire resistance limit of structures used for the construction of the said buildings and structures.

Research is carried out according to the following characteristics:

- Fire resistance level (I, II, III, IV, V)

- Structural fire hazard class (C0, C1, C2, C3)

- Functional fire hazard class

Fire certification of building structures

Fire certification of building structures is carried out according to the following characteristics:

1) The fire resistance limit (not less than 15, 30, 45, 60, 90, 120, 150, 180, 240, 360 minutes) is determined by the characteristics of limit states:

- Loss of bearing capacity (R)

- Loss of integrity (E)

- Loss of thermal insulation capacity (I)

|

Fire resistance rating |

Fire resistance limit of building structures |

||||||

|

Load-bearing walls, columns, and other load-bearing elements |

External non-load-bearing walls |

Interfloor ceilings |

Building structures of attic-less roofs |

Staircase building structures |

|||

|

Flooring (including insulated) |

Trusses, beams, purlins |

Internal walls |

Flights and landings of stairs |

||||

|

I |

R 120 |

E 30 |

REI 60 |

RE 30 |

R 30 |

REI 120 |

R 60 |

|

II |

R 90 |

E 15 |

REI 45 |

RE 15 |

R 15 |

REI 90 |

R 60 |

|

III |

R 45 |

E 15 |

REI 45 |

RE 15 |

R 15 |

REI 60 |

R 45 |

|

IV |

R 15 |

E 15 |

REI 15 |

RE 15 |

R 15 |

REI 45 |

R 15 |

|

V |

Not standardized |

Not standardized |

Not standardized |

Not standardized |

Not standardized |

Not standardized |

Not standardized |

2) Fire hazard class:

- Non-flammable (K0)

- Low fire hazard (K1)

- Moderately fire hazardous (K2)

- Fire hazardous (K3)

|

Building fire hazard class |

Fire hazard class of building structures |

||||

|

Load-bearing rod elements (columns, beams, trusses) |

External walls from the outside |

Walls, partitions, ceilings and attic-less roofs |

Stairwell walls and fire barriers |

Flights and landings of stairs in stairwells |

|

|

CO |

K0 |

K0 |

K0 |

K0 |

K0 |

|

C1 |

K1 |

K2 |

K1 |

K0 |

K0 |

|

C2 |

K3 |

K3 |

K2 |

K1 |

K1 |

|

C3 |

Not standardized |

Not standardized |

Not standardized |

K1 |

K3 |

Fire certification of fire barriers

Fire barriers are three-dimensional building elements designed to prevent fires. These building structures have a standardized fire resistance rating and structural fire hazard class. These include doors, gates, hatches, valves, windows, curtains, walls, partitions, ceilings, gaps, curtains, drapes, screens, water curtains, and mineralized strips.

Fire certification of barriers is carried out according to the following characteristics:

|

Name of fire barriers |

Type of fire barriers |

Fire resistance limit of fire barriers |

Type of filling of openings in fire barriers |

Type of airlock vestibule |

||

|

Walls |

1 |

REI 150 |

1 |

1 |

||

|

2 |

REI 45 |

2 |

2 |

|||

|

Partitions |

1 |

EI 45 |

2 |

1 |

||

|

2 |

EI 15 |

3 |

2 |

|||

|

Transparent partitions with a glazing area of more than 25% |

1 |

EIW 45 |

2 |

1 |

||

|

2 |

EIW 15 |

3 |

2 |

|||

|

Ceilings |

1 |

REI 150 |

1 |

1 |

||

|

2 |

REI 60 |

2 |

1 |

|||

|

3 |

REI 45 |

2 |

1 |

|||

|

4 |

REI 15 |

3 |

2 |

|||

|

Fire resistance of filling openings in fire barriers |

Type of filling of openings |

Fire resistance limit |

||||

|

Doors (except those with more than 25% glazing) |

1 |

EI 60 |

||||

|

2 |

EI 30 |

|||||

|

3 |

EI 15 |

|||||

|

Doors with more than 25% glazing |

1 |

EIW 60 |

||||

|

2 |

EIW 30 |

|||||

|

3 |

EIW 15 |

|||||

|

Fire resistance of filling openings in fire barriers |

Type of filling of openings |

Fire resistance limit |

|

Gates, hatches, valves, curtains and screens |

1 |

EI 60 |

|

2 |

EI 30 |

|

|

3 |

EI 15 |

|

|

Fire resistance of filling openings in fire barriers |

Type of filling of openings |

Fire resistance limit |

|

Smoke- and gas-tight doors (except those with more than 25% glazing) |

1 |

EIS 60 |

|

2 |

EIS 30 |

|

|

3 |

EIS 15 |

|

|

Smoke- and gas-tight doors with glazing of more than 25%, curtains and screens |

1 |

EIWS 60 |

|

2 |

EIWS 30 |

|

|

3 |

EIWS 15 |

|

Fire resistance of filling openings in fire barriers |

Type of filling of openings |

Fire resistance limit |

|

Windows |

1 |

E 60 |

|

2 |

E 30 |

|

|

3 |

E 15 |

|

|

Fire resistance of filling openings in fire barriers |

Type of filling of openings |

Fire resistance limit |

|

Curtains |

1 |

EI 60 |

Fire certification of textile and leather materials

During the fire certification process, textile and leather materials undergo fire safety testing depending on the product:

Curtains and drapes:

- Flammability

- Combustion product toxicity index

- Smoke production coefficient

Bedding:

- Flammability

Elements of upholstered furniture (including leather):

- Flammability

- Spread of flame

- Combustion product toxicity index

- Smoke production coefficient

Special protective clothing:

- Flammability

- Resistance to heat flow

- Thermal insulation efficiency when exposed to flame

Carpets:

- Flammability

- Spread of flame

- Combustion product toxicity index

- Smoke production coefficient

Fire certification schemes.

- Scheme 2c – suitable for serial production products, the permit document is issued based on the analysis of production and product testing;

- Scheme 3c – is intended for serial production products; the permit document is issued on the basis of tests carried out with subsequent inspection control;

- Scheme 4c – includes schemes 2c and 3c , i.e. product testing, inspection control and analysis of the production status;

- Scheme 5c – suitable for mass-produced products, the permit document is issued on the basis of tests conducted in an accredited laboratory, on the basis of a quality management system certificate with subsequent inspection control;

- Scheme 6c – suitable for a batch of products, a fire certificate is issued based on testing of a typical sample removed from this batch;

- Scheme 7c – is intended for a single batch of products, the document is issued based on testing of a single unit of production;

Fire safety certificate validity period:

|

Scheme 2c |

Scheme 3c |

Scheme 4c |

Scheme 5c |

Scheme 6c |

Scheme 7c |

|

1 year |

3 years |

5 years |

5 years |

up to 1 year |

up to 1 year |

Obtaining a fire certificate:

To obtain a fire safety certificate, the following documents will be required depending on the country of origin of the product and the applicable certification scheme:

Russian manufacturer:

- details (company card);

- constituent documents (TIN/OGRN);

- regulatory document according to which the product is manufactured (technical specifications or GOST);

Foreign manufacturer:

- details (company card);

- product name;

- manufacturer's name, address;

- technical description of the product;

- customs code TN VED (if known);

- a contract between the manufacturer and the applicant, in some certification schemes.

Technical documentation (technical descriptions) for substances and materials, including data sheets, specifications, and process regulations, must contain information on the fire hazard indicators of the substances and materials. Mandatory indicators for inclusion in technical documentation are:

1) for gases:

- flammability group;

- autoignition temperature;

- flame propagation concentration limits;

- maximum explosion pressure;

- rate of increase of explosion pressure.

2) for liquids :

- flammability group;

- flash point;

- ignition temperature;

- autoignition temperature;

- temperature limits of flame propagation.

3) for solid substances and materials (except for building materials):

- flammability group;

- ignition temperature;

- autoignition temperature;

- smoke generation coefficient;

- combustion product toxicity index.

4) for solid dispersed substances:

- flammability group;

- autoignition temperature;

- maximum explosion pressure;

- rate of increase of explosion pressure;

- explosion index.

5) for fire protection means:

- area of application;

- fire hazard;

- surface preparation method;

- types and grades of soils;

- method of application to the surface to be protected;

- drying conditions;

- fire protection efficiency of these products;

- a method of protection against adverse climatic influences;

- conditions and service life of fire-protective coatings;

- safety measures when carrying out fire protection works.

The procedure for obtaining a mandatory fire safety certificate.

The certification procedure depends on the certification scheme, product type, and manufacturer's location. After the manufacturer or applicant (seller) has collected the necessary documents, an application is submitted to a certification center . After reviewing the application and analyzing the documents received, the most appropriate certification scheme for the product can be determined.

The basis for issuing the document, as with any other certificate, is a test report, which is issued after positive test results. The testing laboratory where the product is tested for fire safety standards is fully responsible for the correctness of the tests and the accuracy of the data. The process may include an analysis of the production process, in which case the document is issued after the analysis. Once all the main procedures have been completed—product testing has been conducted and the production process has been verified—a fire safety certificate template is prepared to confirm the data. The template already displays the characteristics of your product. Once the template is approved, the certificate itself is issued.

If the certification scheme provides for an analysis of the production status, then the following are checked during the fire certification process:

- technological processes;

- technological documentation;

- technological equipment;

- technological modes;

- management of technological equipment;

- management of metrological equipment;

- testing and measurement methods;

- the procedure for monitoring raw materials and components;

- the procedure for conducting product control during the production process;

- management of nonconforming products;

- procedure for handling complaints.

Deficiencies identified during the audit process are classified as major or minor nonconformities.

Significant disadvantages include:

- lack of regulatory and technological documentation for products;

- lack of description of the operations performed, indicating the technological equipment, points and control procedures;

- lack of necessary technical equipment and means of control and testing;

- the use of control and testing equipment that has not passed metrological control in the established manner and within the established timeframes;

- lack of documented control procedures to ensure the stability of product characteristics, or failure to implement them.

The presence of significant deficiencies indicates unsatisfactory production conditions, and in such cases, obtaining a fire safety certificate is impossible. If one or more significant nonconformities are detected, the manufacturer must implement corrective measures within the timeframe agreed upon with the authorized certification body.

Why do you need a fire certificate?

The unique feature of this document is that it is the only document that can confirm product safety according to fire regulations. This is especially important in Russia due to the constant occurrence of fires caused by poor-quality products or improper handling. Manufacturers of building materials, metal structures, and electrical equipment primarily use this document to prove product safety, as this permit serves as a definitive guarantee of quality.

Having a fire safety certificate, for example, for a product that doesn't require it, can increase sales, as consumers will prefer your product if it has this document. This certificate can also be used to verify the actual product characteristics, such as whether materials are fire-resistant or flame-retardant. This allows every manufacturer to improve the quality of their products for faster sales and increased profitability. Furthermore, a fire safety certificate is a key document, without which a manufacturer cannot participate in government procurement or sign contracts with large companies.

To obtain a fire certificate you must:

- Prepare a set of technical documentation

- Prepare an Application for Certification

- Prepare typical samples for testing

- Prepare arrangements for an expert meeting to analyze the state of production

You can submit a set of technical documentation by email. Certification specialists and experts will review the documentation and determine the certification scheme. Any company, whether registered as a legal entity or sole proprietor, can enter into a fire certification agreement. The agreement specifies the certification scheme, stages and deadlines, as well as the cost of work (services).

Cost of a fire certificate

The cost of a fire safety certificate depends on the type of certified object (product), its purpose, and area of application. In some cases, a fire safety declaration may be sufficient instead of a fire safety certificate, for example, for customs clearance. The cost of fire safety certification services is also determined by who will prepare the test samples for testing—our staff or the client. If any regulatory and technical documentation is missing, you can use our services and include them in the cost of fire safety certification. To determine the exact cost of fire safety certification, please submit an application or request, including a technical description of the product.